Swiss DT 7 & Swiss DT 10

Start simple. Scale effortlessly. Stay ahead.

Want to invest in performance that grows with your business? The Swiss DT 7 & 10 can slash your machining time while ensuring impeccable precision for Electronics, Automotive, Medical & Dental and Micromechanics. The modular design and adaptable configurations can ensure a long-term competitive advantage in our fast-changing industry.

Think small. Win big

In precision machining, smaller can mean smarter. The Swiss DT 7 & 10 combine compact design with advanced engineering to help you produce more with less: less space, less time, less cost.

Affordable by design

With a footprint that’s 25% smaller than comparable 6-axis machines, and the most cost-effective entry point in its class, plus deferred payment options up to 9 months, Swiss DT 7 & 10 deliver premium Swiss-type performance with an attractive price tag.

Smart, scalable, and future-ready

With modular flexibility and up to 33 tools, you can adapt quickly to changing needs without reinvesting in new hardware.

Reliable, high-performance output

With 10% faster cycle times, high-frequency air spindles, and precise 6-axis alignment, you get repeatable, high-quality results, shift after shift, batch after batch.

Medical & Dental

Swiss accuracy meets Medical & Dental complexity

- Fast changeovers (15% faster setups) for custom production

- High repeatability for surgical-grade parts

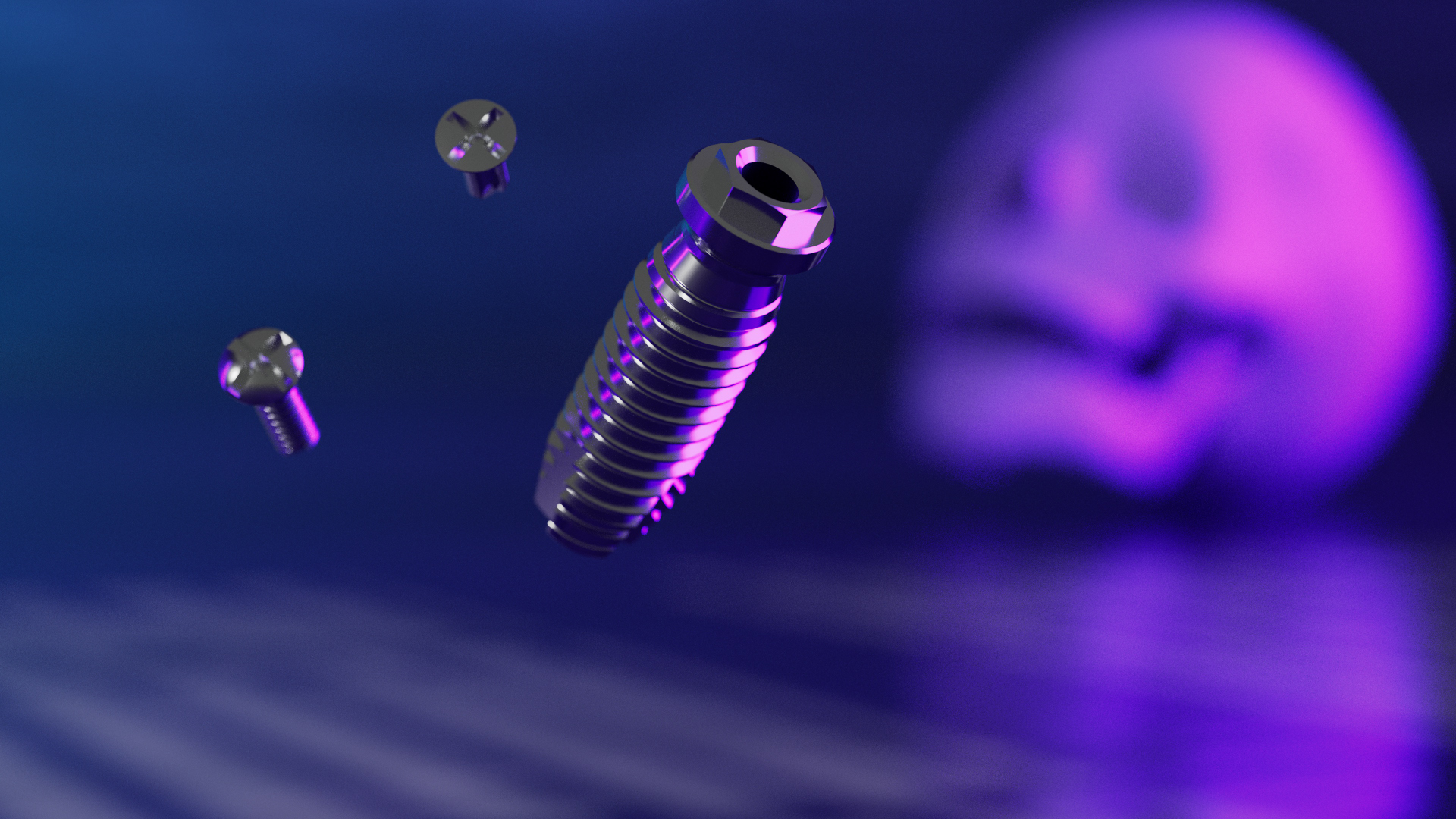

Micromechanics

Where microns matter: Swiss precision you can count on

- 33-tool capacity for versatile operations

- Ideal for tiny components like gear shafts or screws Medical & Dental

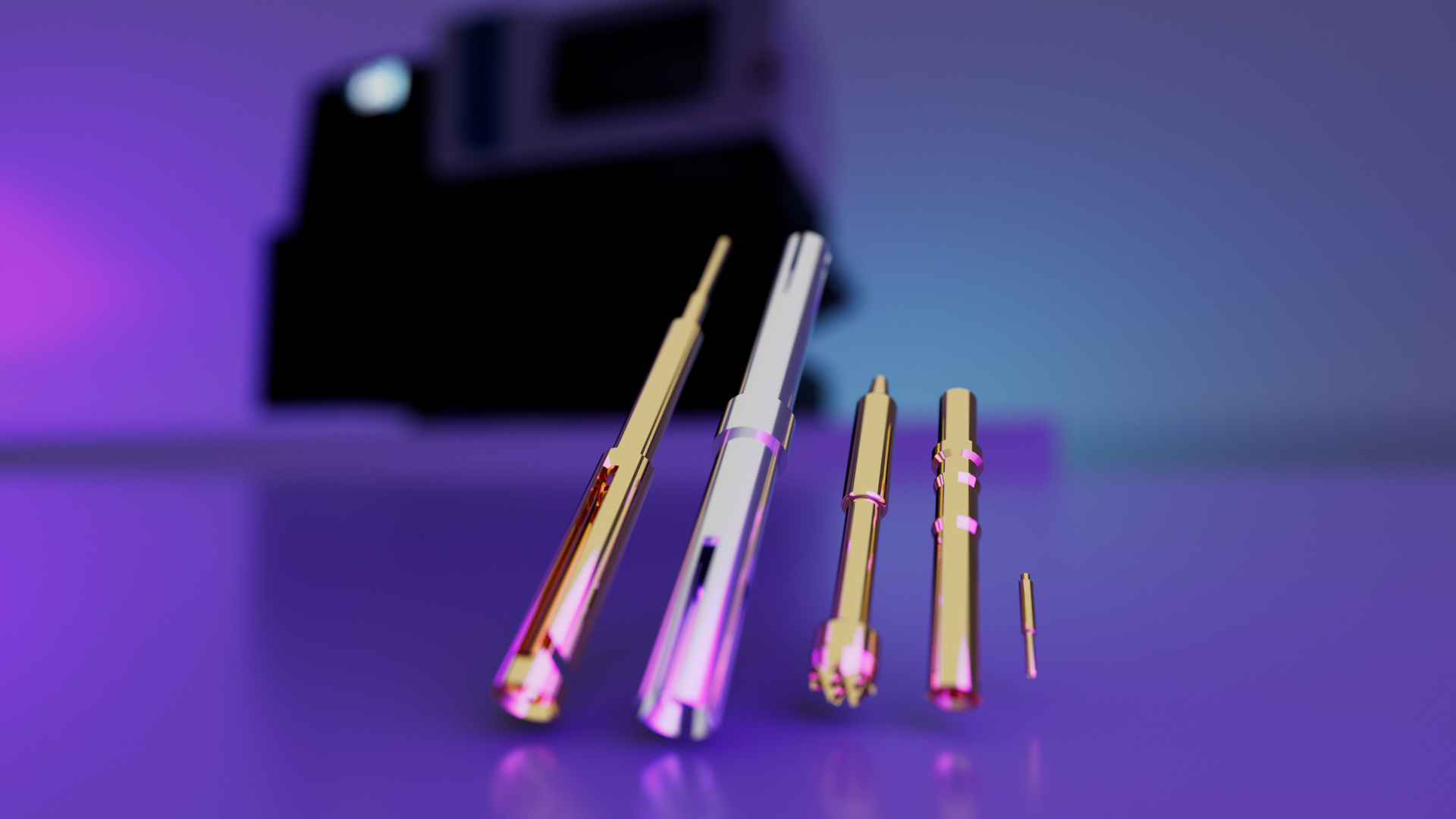

Electronics

Precision electronics demand a precision platform

- High-frequency spindles enable fine surface finishes

- Compact build fits modern production facilities Micromechanics

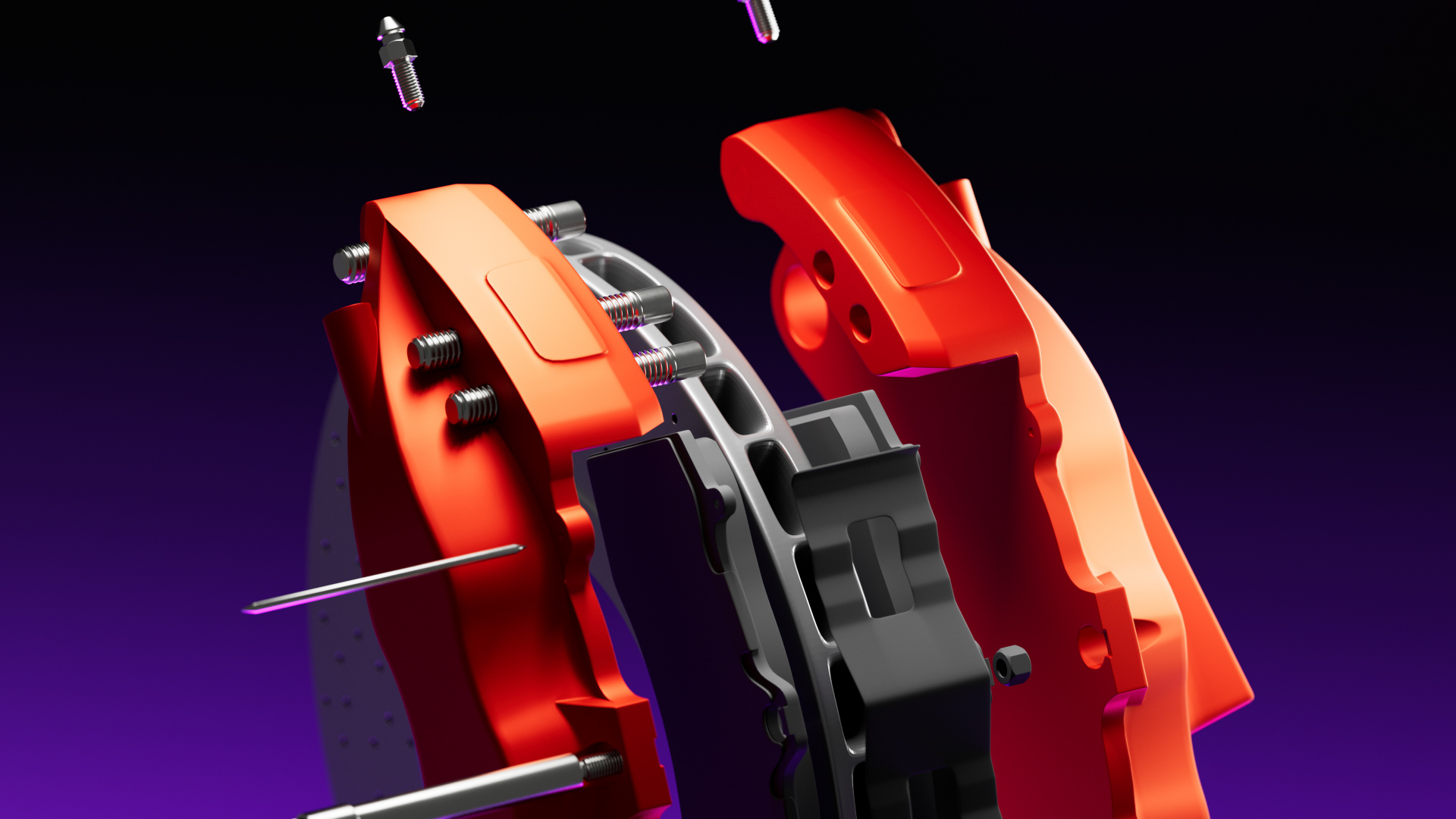

Automotive

Drive down costs. Shift up performance

- Perfect for tight-tolerance connectors and bushings

- High output with short cycle times

| Swiss DT | 7/6 | 10/6 | |

|---|---|---|---|

| Diameter |

mm/in |

7 / 0,276 | 10 / 0,39 |

| Standard workpiece length with guide bush | 185 / 7,28 | 185 / 7,28 | |

| Maximum number of tools | 33 | 33 | |

| Maximum number of rotating tools | 8 | 8 | |

| Plug-and-play B axis | - | - | |

| Spindle power (S1/S6) |

kW/hp |

4.0 (5.0) / 5.36 (6.70) | 4.0 (5.0) / 5.36 (6.70) |

| Counter spindle power (S1/S6) |

kW/hp |

4.0 (5.0) / 5.36 (6.70) | 4.0 (5.0) / 5.36 (6.70) |

| Direct-drive guide bush | No | No |